It’s hard to ignore the impact of supply chains on performance and profitability, with constant disruptions due to global events significantly affecting bottom lines. However, businesses that only give this their attention during times of major shock could be missing out. You can transform your profitability through a combination of small but significant improvements.

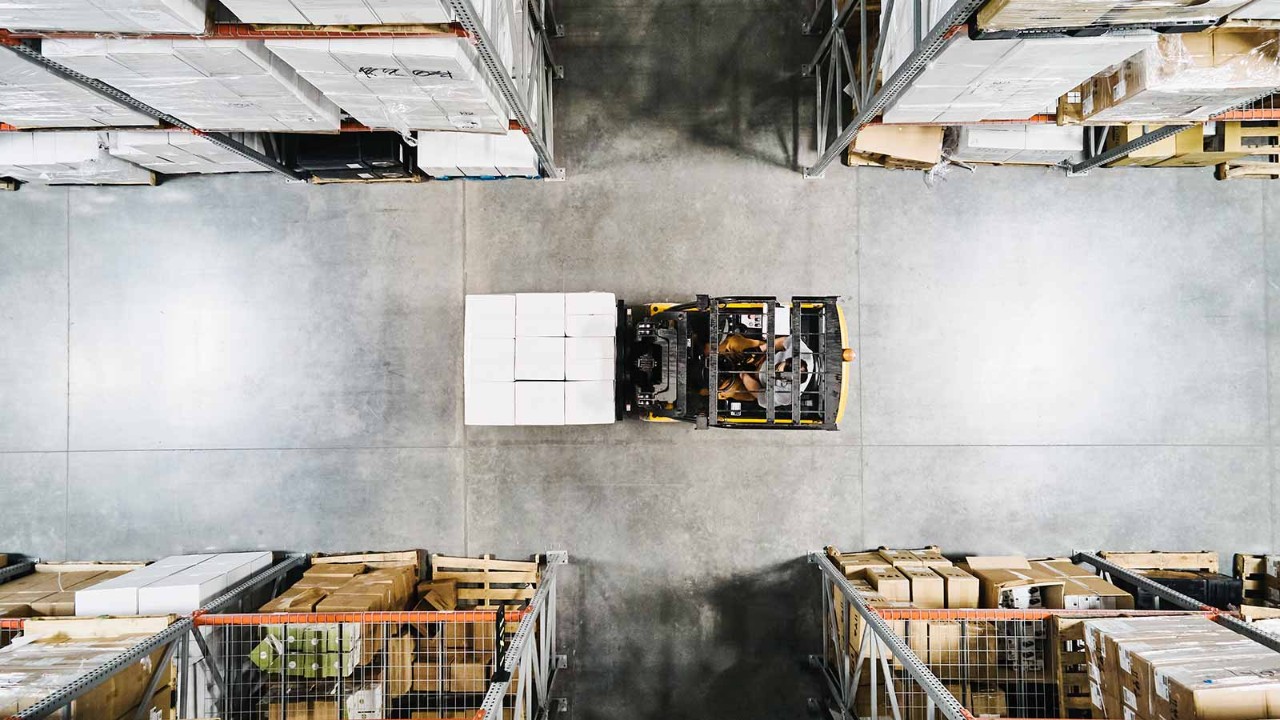

Supply chains are in fact networks that require many activities and decisions to be orchestrated with precision. So it’s important to understand which aspects are adding value and which are generating unnecessary costs.

It is important to assess if you are removing cost from the whole supply chain or simply transferring the burden

Apparently small changes in operating costs can have a big impact on profit margins due to the multiplier or ‘ratchet’ effect. For example, modest reductions of 5% or 10% in labour or overheads can drive a 70% gain in profit margin.

Knowing what customers actually think about your business is critical. Management needs to combine quantitative measurement with a qualitative assessment of customers’ views in order to spot opportunities and competitive risks. This can then be used as a key input or business case for any realignment of the supply chain operation.

Leveraging relationships

Technology can assist significantly in capturing and applying information from across the supply chain network. For example, a straightforward Pareto analysis based on sales revenues can provide a starting point.

However, it’s not all about data. Working with partners in the supply chain to spot opportunities to create mutual benefits and recognising that costs, and savings, inevitably flow and circulate around the network can make a significant difference.

It is likely there will be relatively few partners of sufficient scale and capability to form truly collaborative supply chains, but once identified, these stakeholders can make a pivotal contribution to transforming ways of working and enabling both cost and capital efficiencies.

The case for assessing operational costs

Confirming how operational performance is determining profitability for your business enables you to:

- qualify the relationship of service to cost and determine any trade-offs with greater precision

- target cost reductions at non-value-adding activities

- confirm the operational capabilities that can act as growth drivers and enhance business-wide understanding and confidence.

To truly deliver sustainable profitability improvement, however, you need to ensure current performance data is:

- captured accurately, reflecting true customer experience

- applied intelligently to assign costs to activities, products and customers

- evaluated within the context of the business and the wider supply network

- used to answer key questions about the characteristics and requirements of the operation

- applied to set key priorities for the business and drive the alignment of teams.

‘Value engineering’ offers a rigorous approach to testing cost versus value

Reducing costs

Looking at material costs in the supply chain and applying cost reduction programmes is nothing new. Goals to reduce costs by, say, 10% may appear modest and realistic, but efforts to achieve this target can extend beyond the current reporting year, and in many instances bring unintended consequences as other inefficiencies start to accrue.

So it is important to consider the coherence of cost-reduction opportunities and assess if the change will remove cost from the whole supply chain or simply transfer the burden. Assessing potential cost reductions from one end of the supply chain to the other will help to identify sustainable options.

Product design, materials and components all have a bearing on costs, but the business needs to calculate the value placed upon each of these by the end-customer before making changes. ‘Value engineering’, pioneered by General Electric, offers a rigorous approach to testing cost versus value.

Productivity

Labour efficiencies tend to drift without a systematic approach. Good practices may be lost with staff turnover as knowledge leaves the business. Productivity measures and incentives need to be balanced with a total-supply-chain-cost perspective, and constructed using activity-based costing to allocate fixed costs.

Overheads

The process-related costs of planning, sourcing and distribution are often overlooked. In many instances, simply identifying and analysing these indirect costs will reveal significant opportunities for savings.

The overhead costs of managing the supply network can be high. Capturing the individual cost elements allows management to evaluate the value added and to reassess the approaches being taken.

Understanding total cost-to-serve allows your business to make the most informed decisions and seek cost reductions that are sustainable. Simply passing cost around the supply network will not ultimately deliver savings, and may hamper collaboration and limit the ability of one network to compete with others.

More information

See ACCA’s toolkit to support SMEs and their advisers in establishing a supply chain code of conduct